Image source: Getty Images

An ABC analysis helps businesses prioritize inventory and increase profit margins as a result. This guide will help you understand what an ABC analysis is and how to perform one in your business.

If you feel like you’re treading water as a business, sometimes the problem boils down to a question of priorities.

You’ve been selling a range of products for so long you’ve never stopped to ask yourself whether some products should get priority over others. And as a result, you’re spending half your time on one product and half your time managing the other — even though one brings in far more revenue than the other and should, arguably, get far more of your attention and effort.

That’s where an ABC analysis comes in. This analysis has become a staple in inventory management, allowing companies to take a deep look at their products and start prioritizing which products should get the bulk of their attention.

An ABC analysis helps a business owner determine what type of inventory management system is best for the company. Here’s how to perform your own analysis and set your company on a course for more profitability.

Overview: What is ABC analysis in inventory management?

ABC analysis is a method for categorizing inventory in a way that helps the manager determine which items are having the biggest impact on overall inventory cost, which allows them to make decisions on tracking and prioritizing inventory.

Put another way, an ABC inventory analysis helps an inventory manager classify items based on their consumption values, which is the total value of an item consumed over a set period, usually a year.

It’s similar to the Pareto principle, which holds that 20% of the goods are responsible for 80% of the revenue — and therefore, a manager should focus on that highly impactful 20%. Similarly, an ABC analysis gives the inventory manager an opportunity to identify and focus on those highest-value inventory items.

5 benefits of using ABC analysis for your inventory management

The information gleaned from an ABC analysis offers five key benefits that allow a firm to optimize its inventory. The results show the importance of inventory management practices and what impact they can have on a company’s bottom line.

1. Greater control over inventory

An ABC analysis gives an inventory manager more control over the inventory by enhancing the availability of high-priority products. It also helps the manager control inventory costs and reduce them, as well as minimize losses and improve space management. Team members are able to operate more efficiently through this improved control, which allows them to get more done and enables a company to operate with a smaller staff.

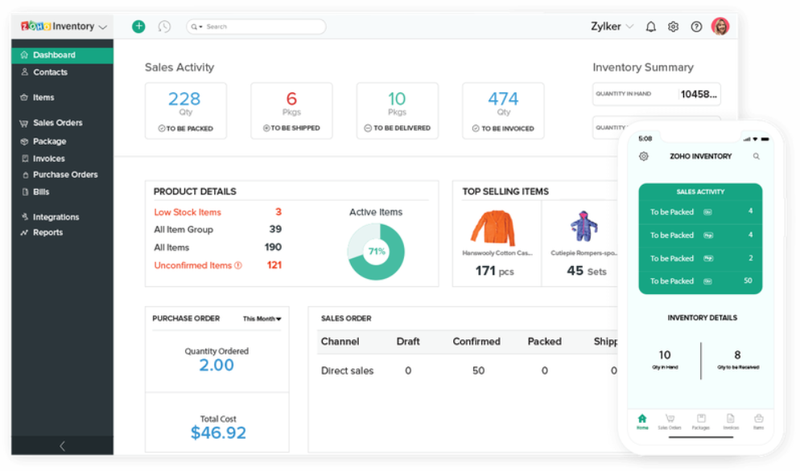

Featured software tool: Zoho Inventory’s dashboard gives you a bird’s-eye view of your inventory, which makes controlling it a lot easier.

Zoho Inventory’s dashboard provides easy access to critical inventory data. Image source: Author

2. Enhanced stock management

The analysis also improves the management of the stock itself, allowing the company to more efficiently allocate resources and improve time management. This results in greater cost-efficacy and helps the company determine the best products to prioritize. It also results in a greater understanding of customer needs, improving how the company interacts with those customers as a result.

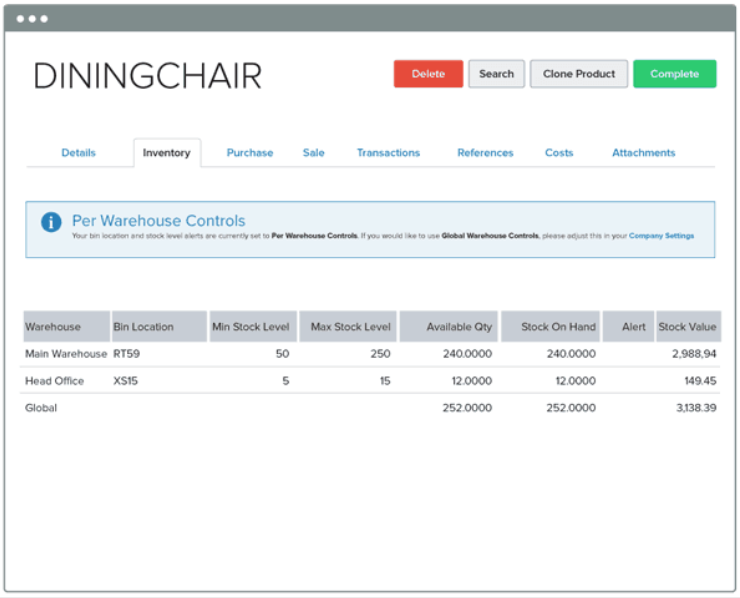

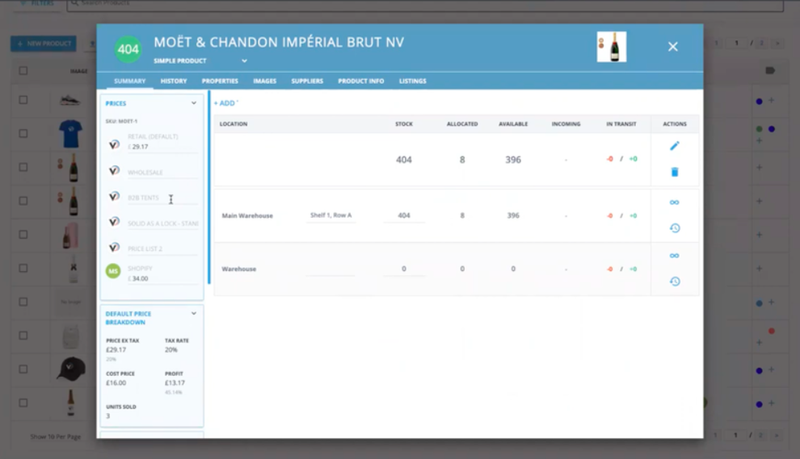

Featured software tool: Unleashed has an Inventory tab that lets you see exactly how much stock you have on hand, both in terms of available quantity and total stock value.

Unleashed allows the user to instantly view how much stock is on hand, as well as value and other vital details. Image source: Author

3. Improved forecasting

With an ABC analysis comes better forecasting — the company understands future product needs and can determine what customer demand will look like months or even years down the road. This provides more opportunities to simultaneously reduce costs and increase profits, and it gives a company more flexibility in responding and adapting to changes in the market.

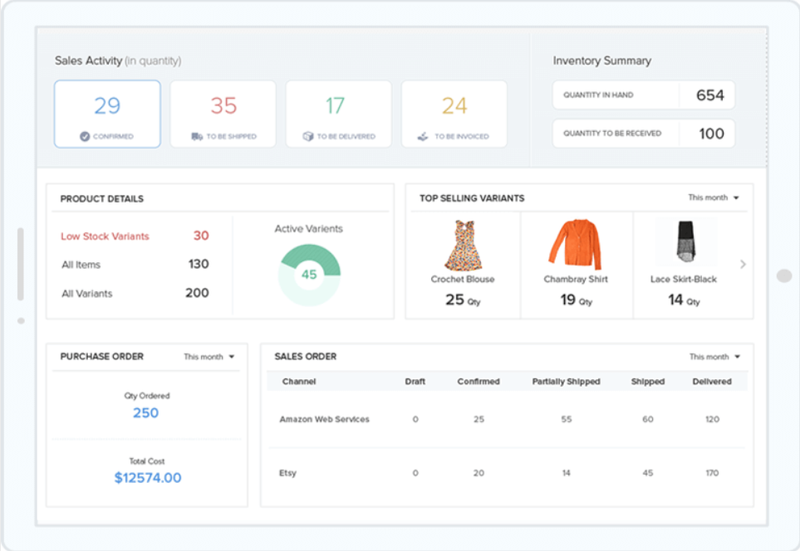

Featured software tool: Zoho Inventory offers custom reports to help you with forecasting future inventory needs.

Zoho Inventory has a reports system to help you figure out ongoing inventory needs. Image source: Author

4. Better deals with suppliers

Another overlooked aspect of better inventory management through an ABC analysis: lower costs through better deals with suppliers. By having a detailed understanding of what inventory levels should look like, a company can leverage savings through bulk-buying opportunities and negotiate the best prices. The company can reduce the risk of excess inventory and forge long-term deals, ultimately resulting in a boost in profits.

Featured software tool: Veeqo’s product management tool helps retailers manage their relationships with suppliers.

Veeqo allows the user to dial up any product and see every relevant detail about it. Image source: Author

5. Pricing power

An ABC analysis also helps with pricing. A business can use it to determine which are the best-selling items and raise prices on goods that are flying off the shelves. Alternatively, the company can identify less-popular products and create a new marketing or sales approach to give them a boost — or make the decision to cut them all together to focus on the more profitable products, as the Pareto principle suggests.

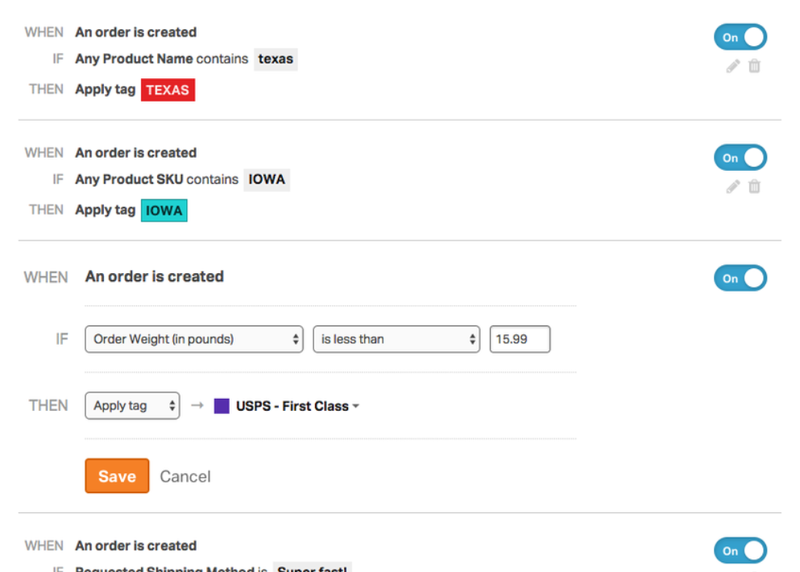

Featured software tool: Ordoro offers custom rules that allow you to automate which items have priority based on price, SKU, or other criteria.

Ordoro uses automations to increase efficiency in prioritizing products. Image source: Author

How to implement ABC analysis within your business

That all sounds great, but how do you implement an ABC analysis within your own business? It only takes the following four simple steps to come up with a breakdown you can use to make some important decisions about inventory.

1. Identify the problem

The first step in an ABC analysis is to identify what problem you are facing. You must ask yourself a few specific questions about your current situation. Where are you lacking? What is inefficient about your operation? What are the significant costs you’d like to cut? What is costing you in terms of time?

2. Gather data

Every analysis requires data, so if you’re not gathering data, you must start right away. Identify which items have the highest costs and which ones cost the least. Collect data on inventory shrinkage, how products are selling, how quickly they’re moving out the door, and what the inventory turnover ratio looks like.

3. Start categorizing

With data in hand, it’s time to start the analysis by placing items in their proper stock categories. Sort the items into groups A, B, and C. A items are the top-priority items with the highest consumption value, B items are important but have a lower consumption value, and C items are the lowest priority.

4. ABC method analysis

Now that your products are categorized, determine the space, cost, and sales for each. Identify which products you should spend more on and which should receive less — or be cut altogether.

Specify which goods to store and determine changes in price. An ABC calculation should show which products are driving revenue, and you should base how much time you spend focusing on those products on what percentage of revenue they bring in.

Example of ABC analysis

Here’s a hypothetical ABC analysis example so you can see how a company might put it into practice:

ACME Widgets Inc. has determined that 20% of its products are its most profitable items and bring in 80% of the revenue, and therefore should be its highest priority. The company has placed 30% of the products in Category B — they’re profitable, but only bring in 15% of the revenue in comparison.

The remaining 50% of its products are in Category C due to razor-thin profit margins or losses in some cases, and as a result, only bring in 5% of company revenue.

After studying this analysis, ACME Widgets Inc. decided to prioritize that 20% of widgets, ensuring proper space is allocated to storing them, instructing staff to prioritize filling those orders as soon as possible and directing the sales and marketing department to focus on pushing those products.

The company focuses 15% of its time on Category B products, and the remaining 5% on Category C products, choosing to shut down production of a significant portion of those products to free up time for higher-priority products.

Use software to perform an ABC analysis

The best way to perform proper ABC management is with software — after all, you can’t do an analysis without proper data anyway, and software is best for that purpose. Inventory management software not only has tools for collecting data but also inventory control features that will help you manage your business better.